Intro To Timers

In essence, pneumatic timers are designed to perform great feats of work through the use of kinetic and potential energy. In any pneumatic system, potential energy, in the form of compressed air, is turned into kinetic energy when the compressed air is allowed to expand. In order to perform any type of work, a pneumatic system has to be able to supply air tanks with the correct amount of air at a given pressure; all pneumatics must be controlled and directed at all times. If a system is not fully monitored and managed, the machinery will not work properly and can malfunction, causing damage to property and human health. A large advantage of pneumatics is the fact that this type of energy can be safely controlled through the use of valves and timers

Pneumatic timers are designed to be functional without the use of electrical currents. These types of products excel in industries where electrical currents are undesirable. A small electric spark can cause devastating damage in many industries that use flammable materials. Basic timers use a piston and a control valve. The air in the system pushes the piston towards the conclusion of a chamber. On the other end of the chamber, a small valve controls the flow of air or inert gases. Timers determine how long it will take for the piston to reach the end of the chamber. The timer creates and fills a vacuum in order to control the system.

In addition to controlling airflow, the piston is sped and slowed by the timer. When too much air builds up in the chamber, the valve at the other end releases air in order to stop the chamber from filling up too quickly. Conversely, the valve also has the ability to close, which stops air from rapidly escaping the chamber. Pneumatic timers can be much more precise because of their ability to control air loss and gains.

In addition to controlling airflow, the piston is sped and slowed by the timer. When too much air builds up in the chamber, the valve at the other end releases air in order to stop the chamber from filling up too quickly. Conversely, the valve also has the ability to close, which stops air from rapidly escaping the chamber. Pneumatic timers can be much more precise because of their ability to control air loss and gains.

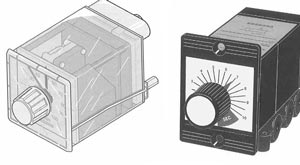

All pneumatic timers have precise controls that allow them to state how much time will go by until the piston opens the chamber. Timers typically come with dials that control how wide the valve opens during an operation. As a result, operators are able to have accurate timing without electrical impulses or timing devices.

If you are interested in pneumatic timers, it is always wise to contact a local professional in the field. There are many different types of timers on the market, and a professional can help you decide what is the best product for your desired application.

Related Reading

- Ellis/Kuhnke Controls

132 Lewis Street Unit A-2, Eatontown, N.J. 07724

Phone: 1-800-221-0714

Fax: 732-291-8154

Email: Info@ekci.com

- Home Pneumatic Controls Technical Info CAD Drawings Contact Us Pneumatic Timers Blog Site Map