Controling Pneumatic Energy

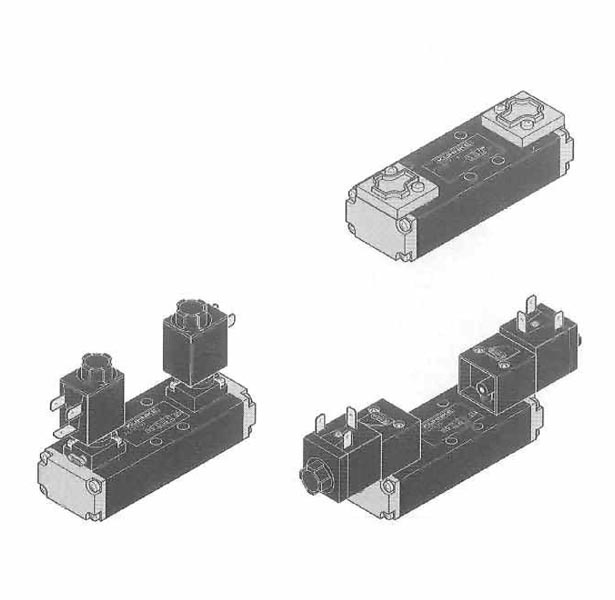

At all times, working energy that is transmitted pneumatically needs to be under the user’s complete direction and control. Useful work by machinery cannot be done if systems are not under control.  There is also the chance that machine operators could be at risk of injury. Fortunately, pneumatic energy is relatively easy to control with the use of pneumatic valves.

There is also the chance that machine operators could be at risk of injury. Fortunately, pneumatic energy is relatively easy to control with the use of pneumatic valves.

The pressure in pneumatic systems is controlled at a minimum of two points (after the compressor, after the receiver tank). To maintain a safe environment, precise control of force is required. Controlling pressure after the receiver tank is necessary because it allows actuators to receive consistent pressure without wasting any energy.

Specific steps must be taken to control pressure after compressors. The energy that is delivered by compressors is not used immediately (potential energy is stored as compressed air). Most compressors are designed into systems to create intermittent operations. A compressor typically drives compressed air to receiver tanks until full.

Pressure switches help with system pressure. Sensing is done with the spring-loaded piston, that is housed within the switch. As pressure lessens, the spring pushes pistons down. After, a contact is made, which causes electrical signals to turn on compressors. As pressure rises in the tank, the piston also goes up. Once the system is at its highest levels of pressure, the piston will break, causing the electrical contact to shut off the compressor.

We carry pneumatic valves to help with the controlling of pneumatic energy. We also sell pneumatic timers and pneumatic indicators. Call us today!

Related Reading for Pneumatic Valves:

- What is a Pneumatic Flow Control Valve?

Different types of pneumatic valves are available, and each is built to serve a specific purpose.

- Safety and Pneumatic Actuators.

- Air Preparation and Pneumatic Valves

- Safety While Using Pneumatic Systems and Tools

- Basics of Directional Control Valves

- Ellis/Kuhnke Controls

132 Lewis Street Unit A-2, Eatontown, N.J. 07724

Phone: 1-800-221-0714

Fax: 732-291-8154

Email: Info@ekci.com

- Home Pneumatic Controls Technical Info CAD Drawings Contact Us Pneumatic Timers Blog Site Map