Maintaining Pneumatic Systems

The maintenance of a pneumatic system is incredibly important. If not maintained properly, it will not work to the best of its ability. Without routine checkups and inspections, the pneumatic system can quickly break down and become damaged. Constant breakdowns and damages will decrease the life of the system and will wind up costing the company additional funds.

All businesses should have a task force of individuals that will regularly check the pneumatic system. These checkups will account for any malfunctioning equipment. The checkups will allow for damages to be fixed, so they do not get any worse.

The pipeline and air layout of the pneumatic system are what cause the most problems. The inspection team should be mindful to pay close attention to these areas of the system. Focusing on these areas ensures the risk of malfunctioning is low.

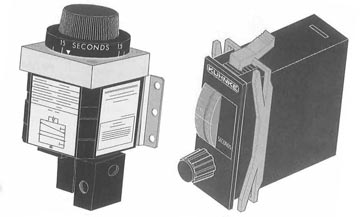

Look at the different equipment of the pneumatic system during the inspection. Carefully examine the pipes, pneumatic valves, pneumatic timers, and pneumatic cylinders. If anything is not working properly, it should be attended to immediately.

When an inspection team is assembled, they should have a set of guidelines to following when checking the pneumatic system. During the review, make sure that there are an accurate circuit and a functional diagram. Clear the impulse valves of all dirt, mechanical shocks, and cooling water.

The imprints of the elements and the units should be visible and accurate. During the inspection, only use the valve openings given by the manufacturer. At times, the dismantling of the cylinders or valves is required. If this happens, take care of the sealing materials.

Related Reading

- Ellis/Kuhnke Controls

132 Lewis Street Unit A-2, Eatontown, N.J. 07724

Phone: 1-800-221-0714

Fax: 732-291-8154

Email: Info@ekci.com

- Home Pneumatic Controls Technical Info CAD Drawings Contact Us Pneumatic Timers Blog Site Map